Table of Contents

- Precision and Quality

- Versatility Across Materials

- Speed and Efficiency

- Automation and Integration

- Cost-Effectiveness

- Sustainability

- Future Trends

The evolution of manufacturing over the past several decades owes much to advancements in laser technology. Today, laser cutting Cleveland, OH, stands out as a pinnacle of precision and reliability for manufacturers seeking to streamline their production processes. From complex automotive components to intricate electronics, laser cutting delivers accurate results with minimal waste, making it a driving force of innovation across a range of industries.

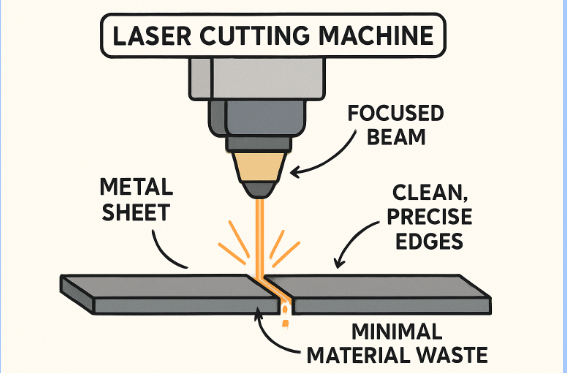

By harnessing focused beams of light, laser cutting eliminates many of the challenges presented by traditional mechanical methods. Whether a business wants rapid prototyping or high-volume production, this method ensures smooth, clean edges and repeatability with every cut. Laser cutting is more than just a tech upgrade; it is a game-changer in both performance and sustainability.

From the shop floors of aerospace manufacturers to the creators of custom signage, companies are recognizing how adaptable modern laser systems have become. The process can handle everything from metals and plastics to wood, textiles, and high-tech composites, offering new creative freedom alongside practical benefits for businesses of all sizes.

In an era when efficiency and precision define competitive advantage, manufacturers that embrace laser cutting are finding themselves able to deliver products faster, with greater quality control, and at a lower cost than ever before.

Precision and Quality

The defining characteristic of laser cutting is the exceptional precision it brings to manufacturing. Advanced machinery consistently achieves tolerances below 0.1 mm, far exceeding the capabilities of other cutting methods. Because the laser beam can be tightly controlled, it produces highly repeatable and consistent results. This precision is invaluable in sectors such as medical device manufacturing and high-tech electronics, where accuracy is not optional but essential.

Laser cutting produces smooth, burr-free edges that often eliminate the need for time-consuming finishing work. By reducing or eliminating post-processing, manufacturers not only streamline their production lines but also significantly reduce material waste. The end result is not just improved productivity but also higher-quality finished parts that meet stringent regulatory and client expectations.

Versatility Across Materials

A major advantage of modern laser systems is their ability to process a wide variety of materials with minimal equipment changeover. Whether cutting metals like steel, aluminum, or titanium, or working with plastics such as acrylics and polycarbonate, laser technology adapts quickly to each material’s unique properties. Even traditionally difficult substrates, such as composites and recycled materials, can be precisely cut, broadening the range of possibilities for designers and engineers.

- Metals (steel, aluminum, copper, titanium)

- Plastics (acrylics, polycarbonate, PVC)

- Wood and MDF

- Paper and textiles

- Composites and recycled materials

Such versatility translates into streamlined manufacturing processes. Companies can often consolidate multiple steps and material types into a single technology, reducing lead times and the complexity of inventory management.

Speed and Efficiency

When it comes to ramping up productivity, laser cutting leads the pack. Cutting speeds typically surpass those of mechanical alternatives, allowing businesses to reduce cycle times and maintain tight delivery schedules. Modern software solutions, such as nesting programs, further optimize this process by arranging cuts to use raw materials as efficiently as possible.

Automated laser systems benefit from rapid changeovers and minimal setup times, which contribute greatly to overall productivity. Manufacturers can transition between different product runs with ease, keeping operations lean and flexible in the face of changing demands. As reported in a recent Forbes article, smart technology adoption in manufacturing is driving record levels of efficiency worldwide.

Automation and Integration

The integration of laser cutting into automated production lines is one of the major developments in modern manufacturing. Automated material handling, loading, and unloading enable continuous, 24/7 operation, reducing the need for human intervention and enabling higher output volumes. Integrated systems also enable real-time data collection and process monitoring, which supports predictive maintenance and further minimizes downtime.

Companies leveraging automation are not just improving efficiency but are also enhancing safety and reliability. Automation reduces the risk of human error and workplace accidents, supporting a safer manufacturing environment and consistent product quality.

Cost-Effectiveness

From prototyping to large-scale production, laser cutting helps manufacturers manage costs effectively. One of its key advantages is the minimization of expensive tooling. Laser-cutting operations are driven by digital patterns, eliminating the need for custom dies or physical molds. This digital-first approach accelerates time-to-market while reducing both initial investments and ongoing maintenance costs.

Additionally, reduced waste, faster turnaround, and lower labor costs all contribute to a compelling value proposition. In many industries, switching to laser technology can help companies remain competitive without sacrificing the integrity or precision of their products.

Sustainability

Sustainability has become a core focus for manufacturers seeking to minimize their environmental impact. Laser cutting directly contributes to greener production by ensuring optimal material usage. Intelligent nesting algorithms optimize part placement on every sheet, reducing offcuts and improving raw material utilization.

Since laser cutting is contactless, it causes less mechanical wear on equipment, resulting in longer machine lifespans and reduced energy waste from maintenance and repairs. These innovations help companies lower their carbon footprint and support broader industry moves toward more responsible resource use.

Future Trends

The integration of AI and machine learning advances laser cutting, enabling real-time monitoring and automatic adjustments to improve quality, reduce interruptions, and increase reliability. As digital transformation advances, laser technology will integrate more closely with Industry 4.0 tools such as predictive analytics and cloud connectivity, maintaining its leadership in smarter, faster, cleaner solutions. Overall, laser cutting transforms manufacturing through precision, versatility, and efficiency, and industry growth is driving manufacturers to invest in this technology to innovate.